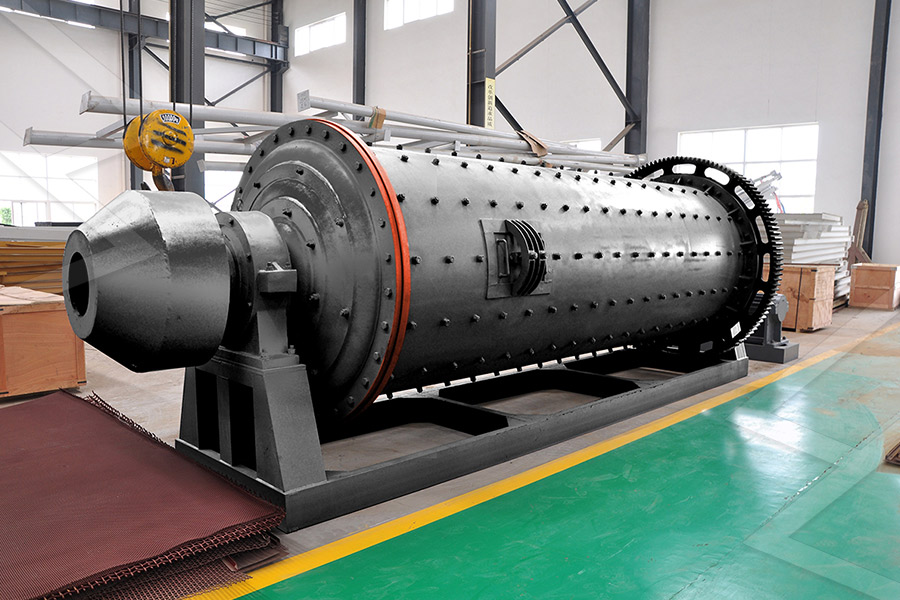

Close Circuit Ball Mill

Closed Circuit Grinding VS Open Circuit Grinding

2016年10月12日 Closed circuit grinding consists of one or more mills discharging ground product to classifiers which in turn return the coarse product from the size separation back to the mill for further grinding2023年9月1日 Fullscale closedcircuit cement ball milling was modeled using a true unsteadystate simulator (TUSSIM), based on a transient cellbased population balance model (PBM) Modeling of closedcircuit ball milling of cement clinker via a 2013年7月15日 This paper discusses the differences between ball mill circuits closed with cyclones and with screens A methodology is described for equipment sizing and selection (PDF) Energy Efficient Ball Mill Circuit2016年4月11日 This paper discusses the designing and implementation of different linear and nonlinear models and its simulation for a closed loop ball mill grinding circuit and advantages MODELING AND SIMULATION OF A CLOSED LOOP BALL

W159 closed circuit grinding ball mills BS Publications

2021年2月25日 Open circuit grinding to arrive at desired product fineness results in generation of a large number of a very wide range of particle sizes ; some are coarser than the 2013年4月1日 For a closed circuit ball mill flowsheet as represented in Figure 2, a simplified relationship (Equation 1) for relative capacity at different circulating load and classificationClosed circuit ball mill – Basics revisited Request PDF2013年4月1日 Two past approaches, experimental and modelling, for quantifying the effects of classification efficiency and circulating load on the capacity of closed ball mill circuits, are Closed circuit ball mill – Basics revisited ScienceDirect2024年9月14日 Closedcircuit ball mills can bring us higher grinding efficiency, better products, and greater benefits It is a commonly used grinding system in modern mineral processing plantsCirculating closedcircuit grinding ball mill to improve

(PDF) Closed circuit ball mill – Basics revisited

Two past approaches, experimental and modelling, for quantifying the effects of classification efficiency and circulating load on the capacity of closed ball mill circuits, are revisited and discussed in this paperWe bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design, bearing, grinding Closed and Open Circuits Ball Mill for 2017年8月28日 The macrostructural models describing the material flows in closed circuit ball mill grinding include the rules of mass flow for steadystate, the nonlinear character of the mill, 5 MATERIAL FLOW MODELS OF CLOSEDCIRCUIT 2023年3月3日 constraint in a closed ball milling circuit in order to operate with the correct control strategy to maximize throughput while achieving the desired grind size 2 Overview of DeBottlenecking the Ball mill Circuit with Hydrocyclone

.jpg)

Closed circuit ball mill: basics revisited University of

2024年10月31日 Based on experience acquired over the years and the investigative work conducted by FC Bond, it was established that the optimum circulating load for a closed ball 2016年4月11日 Modeling And Simulation Of A Closed Loop Ball Mill Grinding Circuit Proceedings of IRF International Conference, Chennai, India, 20th April 2014, ISBN: 97893 MODELING AND SIMULATION OF A CLOSED LOOP BALL 2023年2月11日 Digital Solutions to Evaluate Ball Mill Circuit Recirculating Load and Performance Jeremy Hanhiniemi1,2, Jun Heo2 1 Julius Kruttschnitt Mineral Research Digital Solutions to Evaluate Ball Mill Circuit Analysis of the efficiency of the grinding process in closed circuit ball mills Improving inner mill accessory (lining mill partition, the output diaphragm and composition of the grinding media) Analysis of the efficiency of the process in closed circuit

(PDF) Supplementary Relationship between

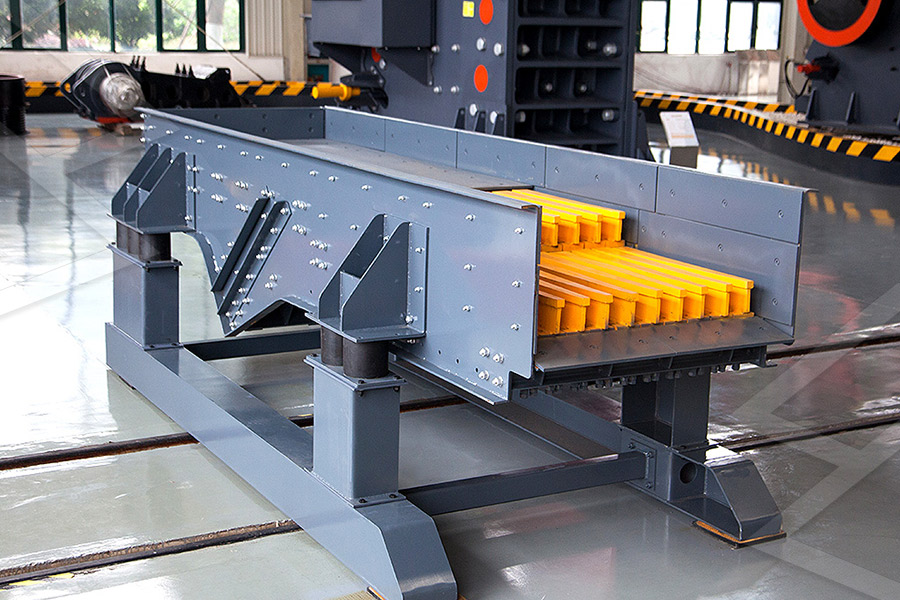

2023年8月15日 This closed circuit ball mill system was closely tested, and the calculated results of statistical data, circulating load, and classific ation efficiency are summarized in Table 3 Although the same2022年12月1日 Closed circuit dry grinding using ball mills is essential in mineral processing industries This process is characterized by significant dead times, highly coupled variables, Control of a closed dry grinding circuit with ball mills using 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk Ball Mill Design/Power CalculationBall mills may operate in a closedcircuit, or opencircuit Closed circuits return a certain amount of the ball mill’s output back to the ball mill for further size reduction A typical closed system Ball Mill (Ball Mills Explained) saVRee

.jpg)

Analysis of the efficiency of the grinding

2016年1月1日 The traditional model of closed circuit ball milling systems has been used for several decades, however, if the classifier of the closed circuit ball mill system performs the duties of both pre 2024年3月15日 closedcircuitballmill Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses NSI Equipments Pvt Ltd, a company that manufactures ball mills for industrial use It provides Closed Circuit Ball Mill PDF Mill (Grinding)Ball mill is the cement crushing equipment in the cement plant Compared with open circuit ball mill, the closedcircuit ball mill has high efficiency, high output, low cement temperature, and good comprehensive benefit It is the best Ball Mill In Cement Plant Cement Ball Mill2022年12月8日 This paper compares two deconvolution methodologies used to estimate residence time distributions (RTD) in industrial closedcircuit ball mills Parametric and non Estimating Residence Time

.jpg)

Validation of a closed circuit ball mill model Semantic Scholar

Experimental work was undertaken by Metso Process Technology and Innovation to better understand the relationship between classification efficiency and circulating load in closed 2013年1月1日 The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and design However, the potential VALIDATION OF A CLOSED CIRCUIT BALL MILL MODELDownload scientific diagram Closed circuit milling flowsheet from publication: THE BENEFITS OF HIGH CLASSIFICATION EFFICIENCY IN CLOSED BALL MILL CIRCUITS Shortly after the first applications Closed circuit milling flowsheet Download 2012年6月1日 A typical structure of a closedloop circuit for wet grinding consists of a ball mill, sump and classifier [10, approach is most frequently used in ball mill grinding circuits The (PDF) Grinding in Ball Mills: Modeling and Process Control

.jpg)

Mill Circuit Pump Manual 911 Metallurgist

2024年7月26日 crushed ore is fed into a SAG/Ball mill circuit with a median size of approximately 12,000 microns Most SAG Mills are operated in closed circuit with a screen 2013年1月1日 Closed circuit ball mill – Basics revisited Minerals Engineering, v 43–44 (2013), pp 148153 View PDF View article View in Scopus Google Scholar Lestage et al, 2002 Circulating load calculation in mineral processing closed circuit 2015年4月1日 Conventional twocompartment fully airswept KHD Humboldt Wedag® raw meal ball mill operating in closed circuit with a static separator was modelled and simulated to Optimization of a fully airswept dry grinding cement raw meal ball 2023年9月1日 In a closedcircuit ball mill for cementclinker grinding, equipped with a Sturtevanttype air classifier, and in the case of required specific surface of fine products=3, 200 cm2/g by Modeling of closedcircuit ball milling of cement clinker via a

.jpg)

Estimating Residence Time Distributions in

2022年12月8日 This paper compares two deconvolution methodologies used to estimate residence time distributions (RTD) in industrial closedcircuit ball mills Parametric and nonparametric deconvolution 2020年12月2日 As a common grinding equipment in cement plants and thermal power plants, ball mills have simple operation in the grinding process and good continuous working Difference between Open Circuit and Closed Circuit Grinding Ball MillSince the early days, there has been a general consensus within the industry and amongst grinding professionals that classification efficiency and circulating load both have a major Closed circuit ball mill Basics revisited NASA/ADSIn this regard, this concentrate is introduced into the hydrocyclone with a separation limit of 380 microns, and the underflow is rejected to the closedcircuit ball mill for regrinding (Fig 8)Molybdenite grinding circuitclosed

Development of a MIMO fuzzy inference system—PI controller for a closed

2024年7月8日 This article aims to study the implementation of classical proportionalintegrative (PI) controllers and their coupling with the fuzzy inference systems (FISs) in the act of closed Figure 82 shows a flow sheet where the rod mill is in open circuit and the ball mill is in closed circuit with a classifier This is a normal setup as the primary function of a rod mill is to provide OpenCircuit Mill an overview ScienceDirect Topics2015年2月21日 For example your ball mill is in closed circuit with a set of cyclones The grinding mill receives crushed ore feed The pulp densities around your cyclone are sampled Circulating Load Calculation FormulaWe bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design, bearing, grinding Closed and Open Circuits Ball Mill for

.jpg)

5 MATERIAL FLOW MODELS OF CLOSEDCIRCUIT

2017年8月28日 The macrostructural models describing the material flows in closed circuit ball mill grinding include the rules of mass flow for steadystate, the nonlinear character of the mill, 2023年3月3日 constraint in a closed ball milling circuit in order to operate with the correct control strategy to maximize throughput while achieving the desired grind size 2 Overview of DeBottlenecking the Ball mill Circuit with Hydrocyclone 2024年10月31日 Based on experience acquired over the years and the investigative work conducted by FC Bond, it was established that the optimum circulating load for a closed ball Closed circuit ball mill: basics revisited University of 2016年4月11日 Modeling And Simulation Of A Closed Loop Ball Mill Grinding Circuit Proceedings of IRF International Conference, Chennai, India, 20th April 2014, ISBN: 97893 MODELING AND SIMULATION OF A CLOSED LOOP BALL

.jpg)

Digital Solutions to Evaluate Ball Mill Circuit

2023年2月11日 Digital Solutions to Evaluate Ball Mill Circuit Recirculating Load and Performance Jeremy Hanhiniemi1,2, Jun Heo2 1 Julius Kruttschnitt Mineral Research Analysis of the efficiency of the grinding process in closed circuit ball mills Improving inner mill accessory (lining mill partition, the output diaphragm and composition of the grinding media) Analysis of the efficiency of the process in closed circuit 2023年8月15日 This closed circuit ball mill system was closely tested, and the calculated results of statistical data, circulating load, and classific ation efficiency are summarized in Table 3 Although the same(PDF) Supplementary Relationship between 2022年12月1日 Closed circuit dry grinding using ball mills is essential in mineral processing industries This process is characterized by significant dead times, highly coupled variables, Control of a closed dry grinding circuit with ball mills using

Ball Mill Design/Power Calculation

2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk